Why Kapil Precast

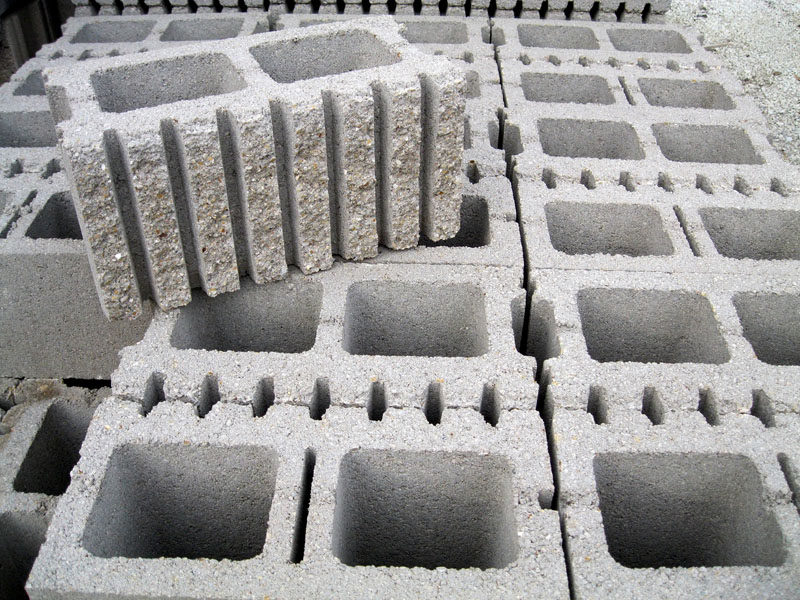

Our Products are manufactured under stringent norms, the raw materials are procured from reputed manufacturers and suppliers are accepted through rigorous quality control norms. Throughout our journey we have handled numerous projects and clients and delivered standout products.

Kapil Precast products have many great features as they are prepared by the raw materials that are procured from reputed manufacturers and suppliers who have a history of supplying top quality materials.

At Kapil Precast we design and construct precast office buildings that meet the requirements of our clients and also the social environment. From designs to delivery information, everything is discussed, governed and monitored by a group of experienced engineers to give the best possible product that not only meets the client's imagination but is also parallel to the modern office architecture.

| S.No | PROPERTY | TRADITIONAL BOUNDARY WALL | PRE-STRESS PRE CAST BOUNDARY WALL | REMARKS |

|---|---|---|---|---|

| 1 | Construction Time | 100 meter wall requires at least 7 days to construct and another 7 days for water curing | 100 meter wall can be constructed in only 2 days | PSPC BW save precious construction time |

| 2 | Strength | The weakest part of this wall is its 150 mm thick brick masonry which can be easily broken by ordinary hand tools for theft. | PSPC panels consist of high tensile wire at every 75 mm distance and can cut only by mechanical means. | PSPC BW provides more better security for industrial campus |

| 3 | Durability | Less as it depends on the quality of plaster and that depends upon several factors like plaster, its thickness, quality of sand, quality of curing, workmanship etc.. | Very high as PSPC panel are made of void less dense high grade concrete and has smooth concrete surface. | PSPC BW has almost NIL maintenance cost. |

| 4 | Weight | Approximate 600 kg/RMTt | Approximate 205kg/RMT | PSPC BW required small foundations |

| 5 | Repair ability | In case of cover turning failure a large section of BW may damage and require almost new construction as repair and require several week time to repair. | In case of failure only few columns may get damaged and require to be replaced. Almost all the panels can be reused in repair in negligible time | PSPC BW has almost NIL repair cost and fast work ability. |

| 6 | Paint | Painting is must, as plastered surface is susceptible to weather decay | Painting is optional and can only for decorative purpose | PSPC BW saves painting cost. |

| 7 | Re-use | Cannot be re used as entire construction is of permanent type. | Almost 100% panel and 60% columns can be reused. | PSPC BW saves lots o cost |

| 8 | Weathering effect | As plaster surface adsorbs moisture, resulting cracks and peels off. It requires periodically re plaster the boundary wall. | There is almost nil moisture absorption as panel surfaces are made of dense concrete and requires no | PSPC BW has almost nil maintenance cost. |

| 9 | Cleaning | Moisture absorbed in plastered surface attracts dust, fungus, algid; plants etc., and requires periodically cleaning and repainting. | No special cleaning required, only washing can make your BW new again. | PSPC BW save cleaning cost. |

Our Products

Our compound walls are designed and built using first class building material that gives the wall long lasting strength and rigidity.

Need more information

Call us today

.jpg)